Introduction: The Art of Drape and Warmth

Shawls, stoles, and wraps occupy a unique space in the textile market, bridging fashion, function, and comfort. For procurement professionals and designers, selecting the optimal yarn for these accessories is a critical decision that dictates the product’s final character, market positioning, and profitability. The common question—”What is a good yarn count for a shawl?”—is central to this process, but the answer is not a single number. The “best” count is a strategic choice determined by a triad of factors: desired drape and hand-feel, intended weight and warmth, and the target aesthetic or construction method (woven vs. knitted). This guide provides a comprehensive, data-driven framework for making these decisions, empowering you to develop shawls that resonate with specific consumer needs and market niches.

Table of Contents

- Demystifying Yarn Count: The Language of Fineness. The Technical Guide to Shawl and Wrap Yarn Counts

- The Strategic Spectrum: Mapping Yarn Count to Shawl Characteristics

- 2.1 Fine & Sheer (Nm 60/2 to Nm 100/2+): The Ethereal Layer

- 2.2 Lightweight & Versatile (Nm 30/2 to Nm 60/2): The Everyday Elegance

- 2.3 Mid-Weight & Cozy (Nm 10/2 to Nm 30/2): The Substantial Wrap

- 2.4 Chunky & Textured (Nm 2/1 to Nm 10/1): The Statement Piece

- Beyond the Count: The Crucial Role of Fiber and Construction

- 3.1 Fiber Selection: From Cashmere to Tencel™

- 3.2 Spinning Method and Yarn Structure

- 3.3 Fabric Construction: Woven vs. Knitted

- Data-Driven Design: Performance and Specification Tables

- Market Trends and Sourcing for Commercial Success

- Conclusion: Building a Winning Shawl Line Through Informed Specification

1. Demystifying Yarn Count: The Language of Fineness

For global sourcing, clarity on terminology is essential. The Metric Yarn Number (Nm) is the most relevant and universal system for the fibers common in shawls (wool, silk, cashmere, cotton).

- Definition: Nm indicates the number of meters of yarn per gram. For example, Nm 50/2 means a 2-ply yarn where the combined single strands yield 50 meters per gram. A higher Nm denotes a finer yarn (more meters per gram), resulting in a lighter, more delicate fabric. A lower Nm indicates a thicker, heavier yarn.

- Ply Matters: Shawl yarns are almost always plied (2-ply, 3-ply, etc.). Plying increases strength, improves stitch definition in knits, and reduces curling. The “ply” designation (e.g., /2) is integral to understanding the final yarn’s thickness and behavior. A single Nm 50 yarn is extremely fine; Nm 50/2 is a workable, fine shawl yarn.

2. The Strategic Spectrum: Mapping Yarn Count to Shawl Characteristics

The choice of yarn count is fundamentally a choice about the shawl’s purpose and personality.

2.1 Fine & Sheer (Nm 60/2 to Nm 100/2+): The Ethereal Layer

- Characteristics: These yarns produce gossamer-light, flowing fabrics with an elegant drape. They offer minimal warmth but maximum style, ideal for fashion layering, bridal wear, or lightweight summer covers.

- Typical Fibers: Cashmere, Merino wool (superfine grades under 18.5 microns), Mulberry silk, Fine cotton. These fibers can be spun to these high counts while maintaining strength and softness.

- Commercial Consideration: This is the luxury and haute couture segment. Raw material costs are high, and production requires skilled handling. The value proposition is exclusivity, sublime softness, and a high-fashion silhouette.

2.2 Lightweight & Versatile (Nm 30/2 to Nm 60/2): The Everyday Elegance

- Characteristics: This is the sweet spot for the premium commercial market. Shawls in this range offer an excellent balance: substantial enough to provide warmth, fine enough for a beautiful drape, and robust enough for everyday use. They are suitable for year-round wear in many climates.

- Typical Fibers: Merino wool, Alpaca, Silk blends, Bamboo, Tencel™. This range allows for beautiful stitch or weave definition and is favored by high-end boutique brands and designers.

- Commercial Consideration: Offers the best balance of perceived value, cost, and wearability. It appeals to a broad consumer base seeking a quality, versatile accessory. A supplier like Glyarn excels in this segment by providing consistent, high-quality yarns in these counts, often with certifications (e.g., RWS wool) that add brand value.

2.3 Mid-Weight & Cozy (Nm 10/2 to Nm 30/2): The Substantial Wrap

- Characteristics: These yarns create dense, warm, and textured fabrics. Drape is more structured, and the shawl feels like a “hug” of warmth. Ideal for cold-weather accessories, oversized winter wraps, and heavily textured patterns (like cables in knits).

- Typical Fibers: Wool, Wool/Alpaca blends, Mohair blends, Thick cotton. These fibers provide the necessary bulk and insulating properties.

- Commercial Consideration: Targets the functional warmth and gift market. Often features bold colors and patterns. Durability and warmth-per-dollar are key selling points.

2.4 Chunky & Textured (Nm 2/1 to Nm 10/1): The Statement Piece

- Characteristics: This category is defined by bold visual and tactile impact. Shawls are quick to knit or weave, very warm, and have a rustic, modern, or avant-garde aesthetic. They are less about drape and more about sculptural presence.

- Typical Fibers: Chunky wool, Felted wool, Roving-style yarns, Novelty thick-and-thin yarns.

- Commercial Consideration: Appeals to the fast-fashion and craft-inspired market. Lower production time can offset material costs. The trend-driven nature of this segment requires agility in sourcing and design.

3. Beyond the Count: The Crucial Role of Fiber and Construction

Yarn count is meaningless without considering the fiber and how the yarn is made.

3.1 Fiber Selection: From Cashmere to Tencel™

The fiber dictates the soul of the shawl:

- Wool & Specialty Animal Fibers: Provide warmth, elasticity, and moisture-wicking. Fineness (micron) determines softness.

- Silk: Adds luster, strength, and a cool, smooth hand. Blends beautifully to add drape.

- Cotton & Linen: Breathable, cool, and inelastic. Produce crisp drape rather than fluid drape.

- Regenerated Cellulosics (Tencel™, Bamboo): Offer brilliant dyeability, a soft, cool hand, and excellent drape, often at a more accessible price point than luxury animal fibers.

3.2 Spinning Method and Yarn Structure

- Worsted vs. Woollen Spun: Worsted-spun yarns (fibers combed parallel) are smoother, stronger, and more durable—ideal for fine, crisp shawls. Woollen-spun yarns (fibers carded randomly) are loftier, lighter, and warmer—perfect for cozy, textured wraps.

- Novelty Yarns: Bouclé, Chenille, Slub, and Tweed yarns add visual and tactile interest. Their effective “count” is less relevant; their character is defined by their structure.

3.3 Fabric Construction: Woven vs. Knitted

- Woven Shawls (e.g., Pashminas, Stoles): Require strong, smooth yarns with high twist. Finer counts (Nm 70/2 – Nm 100/2) create the iconic lightweight yet warm pashmina. The weave structure (twill, plain) also affects drape and warmth.

- Knitted/Woven Knit Shawls: More forgiving of yarn variety. Can utilize everything from fine lace yarns to super-chunky roving. Gauge (stitches per inch) becomes the critical measure alongside yarn thickness.

4. Data-Driven Design: Performance and Specification Tables

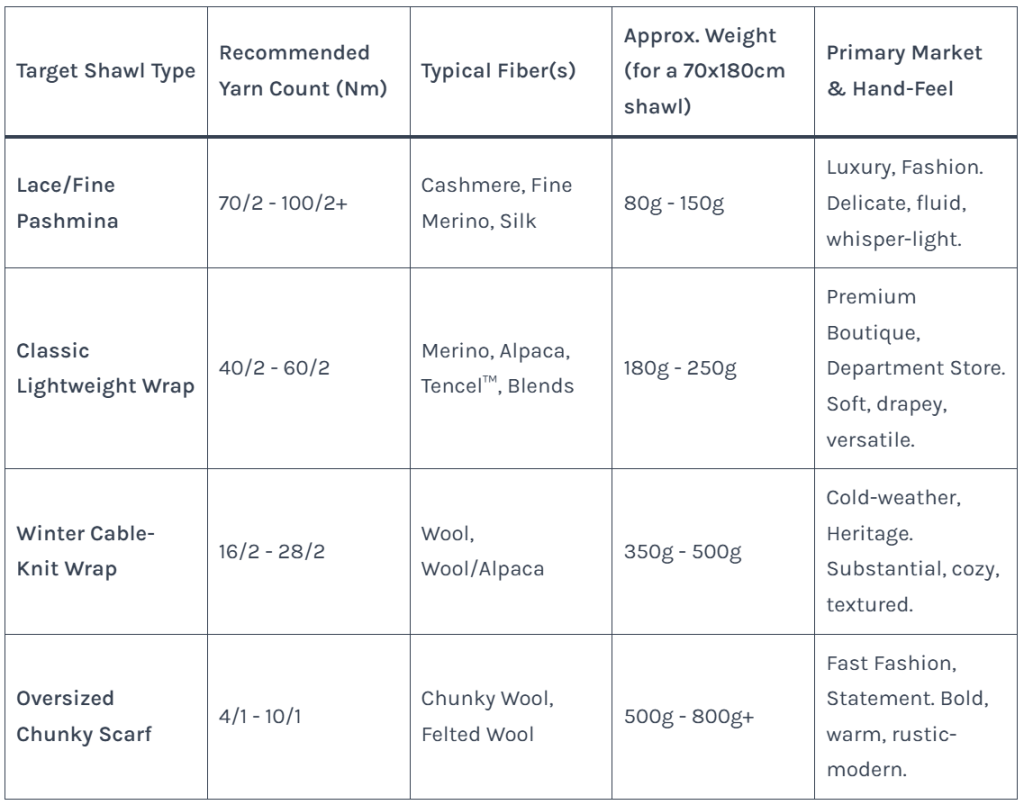

Table 1: Shawl Yarn Count Specification Guide

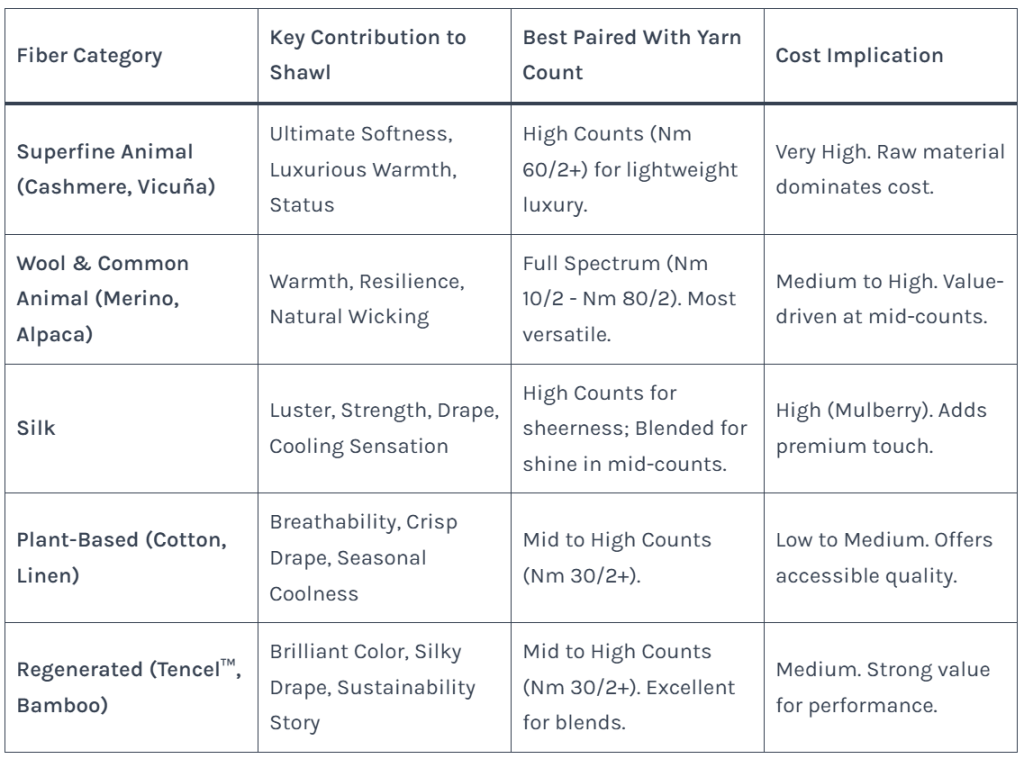

Table 2: Fiber Property Impact on Final Product

5. Market Trends and Sourcing for Commercial Success

The shawl market is influenced by powerful trends:

- Sustainability and Traceability: Demand for RWS-certified wool, recycled fibers, and Oeko-Tex certified dyes is now mainstream. Brands must provide provenance.

- Seasonless Dressing: Versatile, mid-weight wraps (Nm 30/2-50/2) in natural fibers are key, suitable for air-conditioned summers and layered winters.

- Experience-Driven Luxury: Consumers invest in heirloom-quality pieces made from exceptional materials (e.g., baby alpaca in Nm 50/2), valuing craftsmanship over fast fashion.

Sourcing Intelligence: Successful procurement requires moving beyond simple RFQs.

- Work with Technical Partners: A supplier like Glyarn provides more than yarn; they offer material intelligence. For a brand launching a sustainable alpaca wrap line, Glyarn can source RWS-certified alpaca tops, recommend the optimal count (e.g., Nm 40/2 for balance of softness and durability), and connect them with spinners specializing in luxury animal fibers. They act as a supply chain curator and technical consultant, ensuring the final yarn meets both design and ethical specifications.

- Prototype and Test: Always produce a full-scale prototype with the exact yarn. Assess drape, weight, and hand-feel in context.

- Calculate Total Delivered Cost: Factor in spinning waste, minimum order quantities, and logistics. A slightly higher-quality yarn with better yield can have a lower true cost.

6. Conclusion: Building a Winning Shawl Line Through Informed Specification

Selecting the “right” yarn count for a shawl is a nuanced, strategic decision that blends art with material science. There is no universal answer, but a clear methodology.

Actionable Framework for Buyers:

- Define the “Why”: Start with the end-user and occasion. Is it a lightweight fashion accessory, a functional winter layer, or a luxurious gift?

- Select the Fiber Narrative: Choose fibers that support the story (luxury, sustainability, comfort) and deliver the required performance (warmth, drape, breathability).

- Pinpoint the Count and Construction: Use the target weight and hand-feel to narrow the count range, then decide on ply and spin method.

- Partner with Expertise: Collaborate with suppliers who offer technical guidance, quality assurance, and supply chain transparency. A partner like Glyarn bridges the gap between creative vision and commercial reality, ensuring your specifications result in a product that is beautiful, viable, and market-ready.

By applying this disciplined approach, designers and sourcing managers can transform subjective preferences into precise, effective specifications, creating shawl collections that are coherent, desirable, and commercially successful.

Leave a Reply